Profile

Capchem is committed to becoming a leading global enterprise specialized in electronic chemicals and functional materials. The company has highly emphasized on research and development since its establishment, insisted on high level of investment in R&D, fully stimulated innovation vitality,continuously promoted the construction of R&D platforms, improved the technological innovation capability, and driven the high-quality development of itself, the whole industry chain and the whole industry.

Innovation never stops, technology drives services.After nearly 30 years of development, the Capchem has built a multifunctional research and development platform that integrates research, development, technical services, testing and verification, and information management of battery chemicals, organic fluorine chemicals, capacitor chemicals, and semiconductor chemicals.

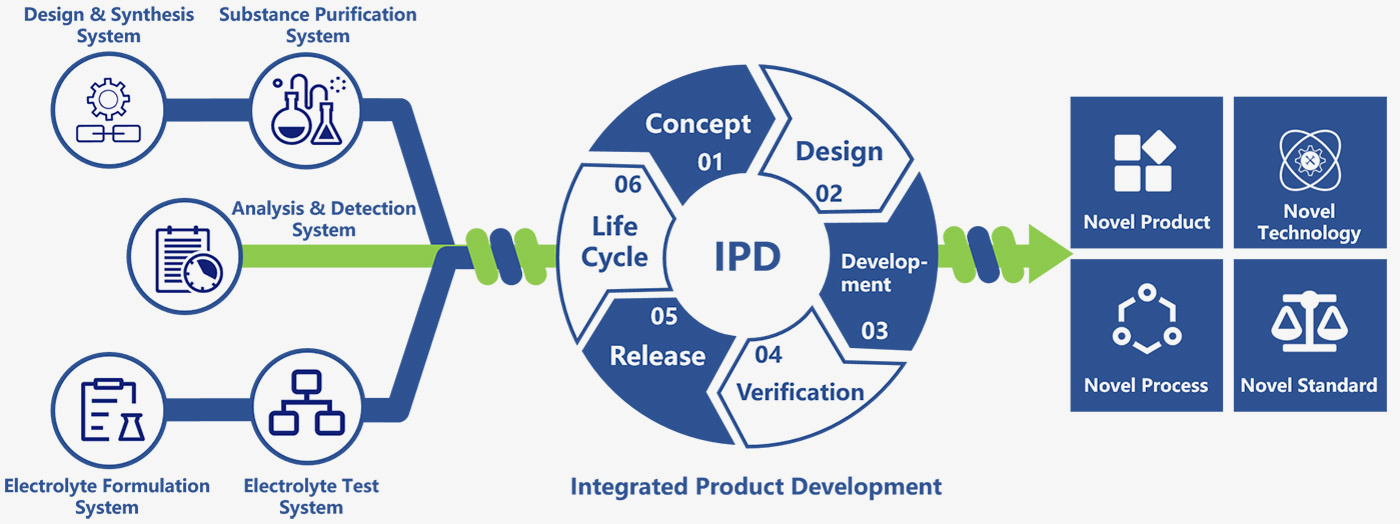

Capchem has built a full cycle R&D platform for “functional material synthesis technology-material purification and refinement technology-microanalysis and testing technology-mechanism research and formulation development-component design and testing”. Capchem has established a robust industry-university-research-application collaboration mechanism with universities, research institutes, and upstream/downstream enterprises across the industrial chain. By addressing industry pain points and technical challenges, Capchem drives technological progress and leads industry development through its independently developed processes technology and scientific achievements, consolidating its leading position in both technology and market.

Laboratory area

R&D personnel

Platforms for R&D and innovation

Patents owned by the Company

R&D Platform

National Enterprise Technology Center

National CNAS Accreditation Testing Center

Guangdong Engineering Technology Research and Development Center for New Electronic Chemicals

Guangdong-Hong Kong-Macao Optical Thermoelectric Energy Materials and Equipment Joint Laboratory

Shenzhen Key Enterprise Research Institute

Shenzhen Research and Development Center for New Electronic Chemicals

Shenzhen Engineering Laboratory of Li-ion Power Battery Electrolyte

Shenzhen Enterprise Technology Center

Academician (Expert) Workstation

Post-Doctoral Workstation

Post-doctoral Innovation Practice Base

Southern University of Science and Technology-New Zeus Joint Laboratory

Hardware

Capchem Institute has established a technology innovation platform based on five core technology modules: functional material synthesis technology, material purification and refining technology, microanalysis and testing technology, mechanism research and formulation development, component design and testing. The Capchem Research Institute is also equipped with high-performance R&D and testing instruments to facilitate the whole process research from component manufacturing to performance testing and mechanism analysis, so as to provide a steady stream of innovation power for the company's new products and new technology incubation.

Scanning electron microscope

X-ray photoelectron spectrometer

Liquid chromatography-mass spectrometer

Ultra performance liquid chromatograph

Combustion ion chromatograph

Inductively Coupled Plasma Mass Spectrometer (ICP-MS)

Gas chromatograph-mass spectrometer

Nuclear Magnetic Resonance (NMR) Spectrometer

R&D and Innovation Mechanism

Innovation is the core driver for corporate development. Capchem continuously explores innovation to adapt to market changes, meet customer demands, and maintain a competitive advantage. By remaining at the forefront of domestic and international technological developments, we focus on product innovation, process optimization, and product performance enhancement to reduce costs. We also consistently stimulate the innovative vitality of R&D staff and improve our R&D management system. Further efforts are made to promote cooperation and exchange with universities, research institutes, and enterprises in the industry chain, as well as to protect intellectual property rights. Our goal is to promote the high-quality development of the Company.

R&D and Innovation Mechanism

|New Additive

LDY196 (Unsaturated Ester Additive)

Features:

■ The formation of a stable passivating film on the surface of the cathode and anode to improve battery performance.

■ Long Term Cycling Stability. 1C/1C 3000 cycles, Cap. Ret.≥80%.

■ High-thermodynamic stabilities, ensure battery stability up to 85℃.

Scope of application:High nickel ternary battery(NCM), high voltage ternary battery(NCM), silicon-based anode battery.

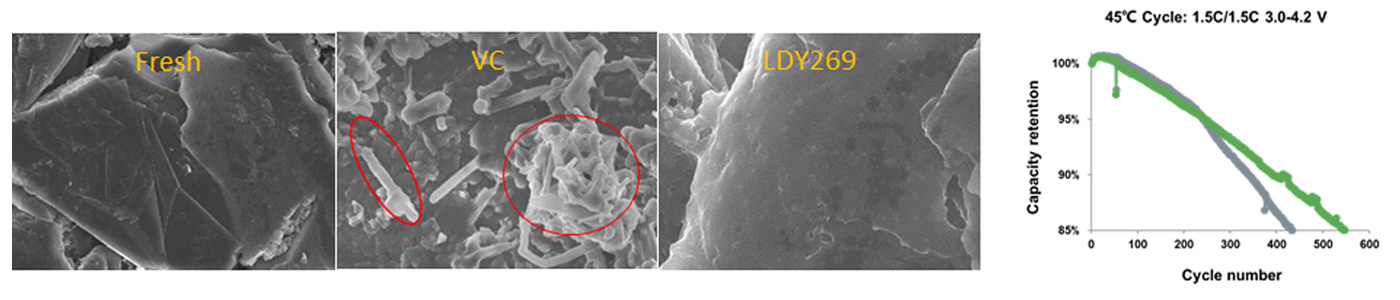

LDY269(Carbonate Ester Additive)

Features:

■Establishing a stable SEI layer to upgrade cycling stability.

■Long Term Cycling Stability. 1C/1C 2500 cycles, Cap. Ret.≥80%.

■Lower battery impedance compared to general film forming additives, such as Vinylene carbonate (VC).

Scope of application: High rate ternary battery、high nickel and high voltage ternary power battery(NCM), high rate start–stop battery, lithium iron phosphate battery.

SCT2584 (New Film-Forming Additive for Cathode and Anode)

Features:

■ A uniform and thinner CEI film is constructed on the surface of the ternary cathode material and the structural phase transformation of ternary cathode material is suppressed.

■ A stable SEI film is formed on the surface of the anode before the Ethylene carbonate (EC), and effectively protect electrodes and prevent electrolyte decomposition on both electrodes.

■ Improving the long-term cycling performance and storage performance of lithium-ion batteries at high voltage and elevated temperature.

■ Suppression of thermal runaway induced by thermal abuse in LCO batteries.

Scope of application: High voltage LCO battery, high nickel/high voltage ternary power battery(NCM), lithium iron manganese phosphate battery(LMFP).

|Digital Products Electrolyte

■ Electrolyte for high voltage LCO battery (4.45~4.53V)

Through the use of new additives with independent intellectual property rights and the optimized regulation of electrolyte formula, the comprehensive performance of higher voltage LCO batteries is effectively guaranteed.

■ Electrolyte for high rate performance LCO battery (4.4~4.5V)

The use of novel solvent combination to achieve excellent electrochemical performance of the battery, including long cycle life, high temperature stability, and low temperature performance under high rate of 2~5 C.

■ Electrolyte for LCO/silicon-based anode lithium-ion battery

New film-forming additives for cathode and anode is adopted to effectively improve the cycle life of the battery and further improve the energy density of the battery.

|Power battery electrolyte

■ Lithium iron phosphate system

Capchem focuses on the research and development of high compaction density and high-areal-density lithium iron phosphate system batteries for passenger cars. Through the synergy of low-viscosity solvents and Infiltrating additives, the Infiltration of electrolyte on high compaction density electrode is improved, thus meeting the requirements of passenger cars for electrochemical performance of the battery, including long cycle life, high temperature storage stability, and low temperature performance.

■ High voltage ternary battery system

The formulations of Capchem are consisted of solvents, lithium salts, and additives with the characteristics of oxidation resistance and wide electrochemical window,which overcomes the problems of poor adaptability and easy decomposition of traditional carbonate electrolyte. which greatly improves the electrochemical performance of the electrolyte at high voltage, realizing the safety, efficiency and durability of batteries at high voltage, and at the same time achieving a cycle life of up to 2,000 cycles or more.

High-voltage-tolerant: cut-off voltage 4.25≤V≤4.5V

Long Term Cycling Stability: 1C/1C 2500 cycles, Cap. Ret.≥80%

■ High nickel ternary battery system

High nickel/silicon-based anode lithium-ion battery: Through the synergy of independent R&D Film-Forming Additives and new fluorinated solvent, this series of products achieve excellent electrochemical performance of the battery, including long cycle life and high temperature-tolerant. 1C/1C 1500 cycles, Cap. Ret.≥80%

|Supercapacitor Electrolyte

■ DLC3702 series: 3.0V high voltage EDLC electrolyte

■ DLC3413/DLC3402 Series: Dual 85 EDLC High Temperature Electrolyte

Application areas: Power grid side energy storage system, Water meter, electricity meter, gas meter.

■ DLC3733 series:-55 ℃ ultra-low temperature EDLC electrolyte

Application areas: Used in cold fields.

| Semiconductor Chemicals

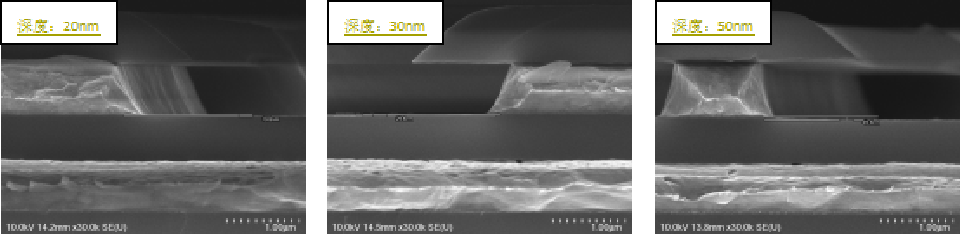

■ Cu/AS one-step etching solution

AS etch rate: 0-20Å/s

Roughness: No difference before and after etching

Metal residue: None

Undercut: none

Service life: ≥ 7000ppm (based on copper ion concentration)

Scope of application:The high-precision etching applied to the high-generation panel copper process can meet the specific requirements of simultaneous etching of the metal semiconductor layer AS, so as to achieve the purpose of eliminating a DRY etching process and greatly reducing the manufacturing cost.

The above figure is the cross-sectional electron microscope of the substrate etched to different AS depths.

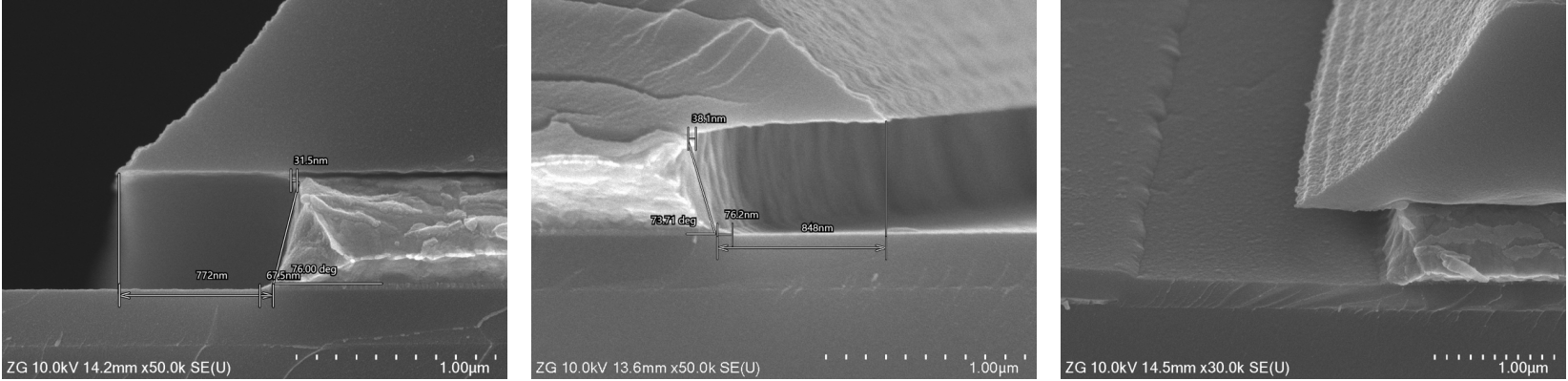

■ IGZO compatible etching solution

IGZO corrosion rate <0.1 Å/s

Roughness: No difference before and after etching

Metal residue: None

Undercut: none

Service life: ≥ 4000ppm (based on copper ion concentration

Scope of application:Applied to high-generation panel copper process high-precision etching, can meet the metal layer etching at the same time, the semiconductor layer IGZO without Damage.

The above figure shows the scanning electron microscope image of the substrate section after etching.

To learn more about the latest products and solutions of the new state, please contact us.