Governance

Capchem strictly complies with laws and regulations such as the Work Safety Law of the People's Republic of China and has established a five-tier management structure consisting of the Board of Directors-Executive Committee-EHS Management Committee-EHS Center-Subsidiaries, providing robust organizational support for intrinsic safety throughout the entire production and operation process, chain, and lifecycle.

Strategy

Capchem upholds the people-oriented development concept, builds the occupational health and safety management policy of Compliance with laws and regulations, life above all; Safety first, with prevention as the focus; People-oriented, striving for green excellence; Scientific management for continuous improvement, and builds comprehensive and multi-level occupational health and safety management system that is collectivize and integrated to closely control all links in the chain of production, storage, use, operation, transport and waste treatment involved in the production and operation of the Company, and to effectively guarantee the safety and order of business operations.

Impact, Risk and Opportunity Management

Capchem firmly established the concept of risk-based EHS management, imported the relevant elements of the chemical process safety management (PSM) system, and embedded the requirements of production safety standardization, safety risk classification and control, and safety hazard investigation and management. Using professional tools and methods such as Hazard and Operability Analysis (HAZOP) and Job Safety Analysis (JSA), Capchem carries out safety risk assessment on a regular basis, systematically identifies the risks and safety hazard involved in materials, processes, equipment, personnel operations, etc.

Capchem has continued to promote the construction of the BCM system, comprehensively revised and upgraded the original safety emergency plan, and improved and formulated the plans for emergency scenarios such as power outages, DCS fault feedback, and bad weather.

Capchem has established a perfect safety performance monitoring and assessment system and formulated the EHS Reward, Punishment and Performance Assessment Management System.

Capchem emphasizes the empowerment of technology to solidify the construction of safety information systems. In 2024, the Company invested nearly 5 million yuan to enhance projects across our bases, including risk monitoring and early warning, management of major hazard sources, intelligent inspections, risk classification control and hidden danger rectification, as well as the onstruction of cybersafety training spaces. By leveraging information technology, Capchem improves the timeliness, accuracy, and efficiency of risk monitoring and early warning, risk classification control and hidden danger rectification, and employee safety awareness and skills at production bases.

Capchem has formulated and complied with the whole process control system, including the Occupational Disease Hazard Monitoring and Evaluation Management System, the Workers' Occupational Health Monitoring and File Management System, and the Occupational Disease Protection Facility Maintenance and Inspection System, so as to ensure that the risks and potential hazards of occupational diseases are effectively monitored and scientifically evaluated.

Capchem continues to improve the production safety responsibility system, strengthen the implementation of responsibilities at all levels, and carry out targeted safety training for all employees.

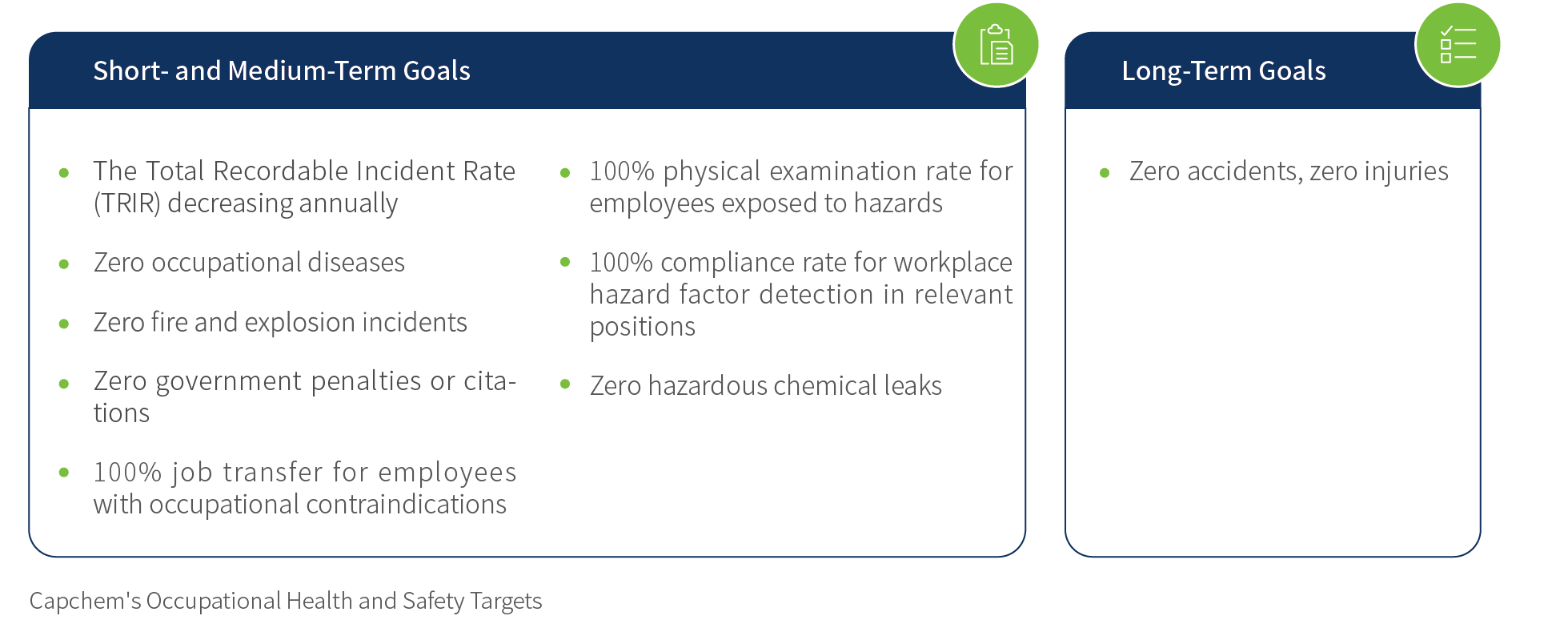

Indicators and Targets

Capchem remains steadfast in advancing our occupational health and safety management efforts, employing multi-dimensional and comprehensive measures and strategies to ensure the successful achievement of this year's occupational health and safety targets. These endeavors lay a solid foundation for the Company's stable operations and the well-being of our employees.

Highlights in 2024

- Cumulative investments in occupational health and safety amounted to RMB 55.45 million

- 100% coverage of emergency drills and safety training sessions for production employees

- No general or more severe work safety accidents, suspected occupational

- Eight operating production bases have obtained ISO 45001 certification