-

-

Strategy&Management

显示更多 -

Environmental

-

Environmental Overview

-

Combating Climate Change

-

Optimizing the Energy Structure

-

Environmental Compliance Management

-

Emissions and Waste

-

Resource and Ecological Protection

显示更多 -

-

Social

-

Social Overview

-

Innovation-driven

-

Product Quality

-

Chemical Safety

-

Occupational Health and Safety

-

Customer Services

-

Responsible Supply Chain

-

People-oriented

-

Community Contributions

显示更多 -

-

Governance

显示更多 -

Report

-

Governance

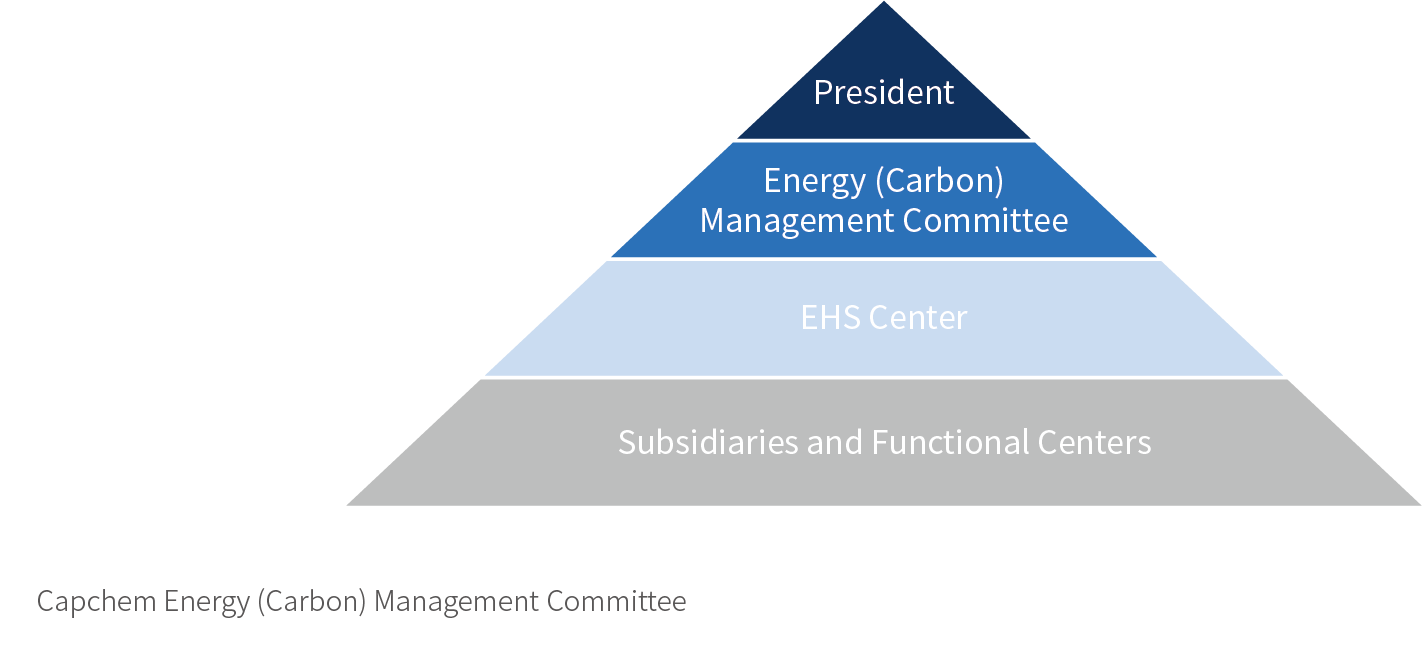

In terms of climate change governance, Capchem has incorporated climate-related impacts, risks and opportunities into the important considerations of the Company's business strategy, established the Energy (Carbon) Management Committee at the level of the board of directors, with the president as the director, based on a "top-down, headquarters-driven base" model. The Company has formulated the Capchem Energy (Carbon) Management System and the Greenhouse Gas Emission Management System and other management systems to comprehensively manage greenhouse gas emissions in the course of production, purchasing and office operations.

Strategy

Based on the Company's development strategy, Capchem has made great efforts to promote internally-driven green development, coordinated the implementation of measures to enhance management capacity, optimize energy structure, strengthen supplier carbon management, and push forward low-carbon rating and certification. The Company insisted on integrating the green and low-carbon concepts into all aspects of its production and operations.

Impact, Risk and Opportunity Management

The Company identifies climate risks and opportunities with significant potential impacts, sorts out their specific types, and evaluates the timeframe of the impacts, taking into account its own business characteristics, internal and external development environments, and expert opinions. The Company comprehensively evaluates the impact of the risks and opportunities on the business model and corporate strategy, value chain and financial position, identifies and evaluates the degree of impact and likelihood of climate-related risks and opportunities based on its operational continuity.

The Company develops response strategies based on identifying climate risks and opportunities, with the Energy (Carbon) Management Committee as the leader, regularly tracking the progress of climate-related actions and plans, carrying out annual assessments of greenhouse gas emission reduction targets, and continually exploring working mechanisms to optimize the management of climate-related risks and opportunities.

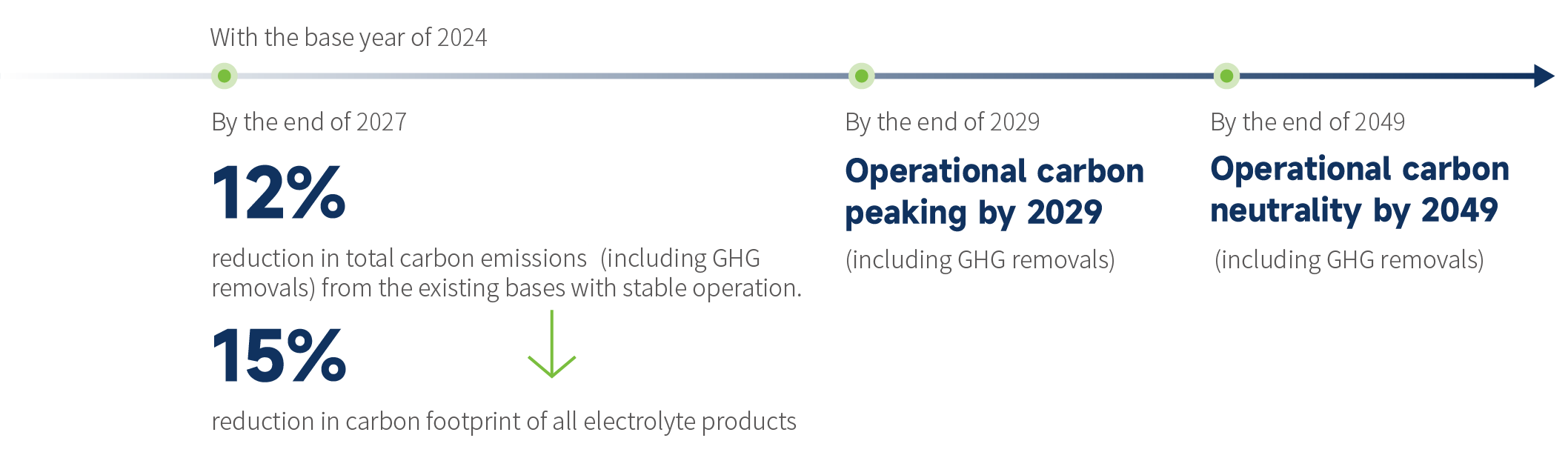

Indicators and Targets

Highlights in 2024

- Published the dual carbon target of "Operational carbon peaking by 2029, Operational carbon neutrality by 2049" and the carbon neutral action plan

- Conducted climate risk and opportunity identification and assessment

- Eight products gained ISO 14067 certificate

Contact Us

Capchem Plaza, Changye Road, Pingshan District, Shenzhen City, China.

Channels

Capchem

online shop