Quality Management System

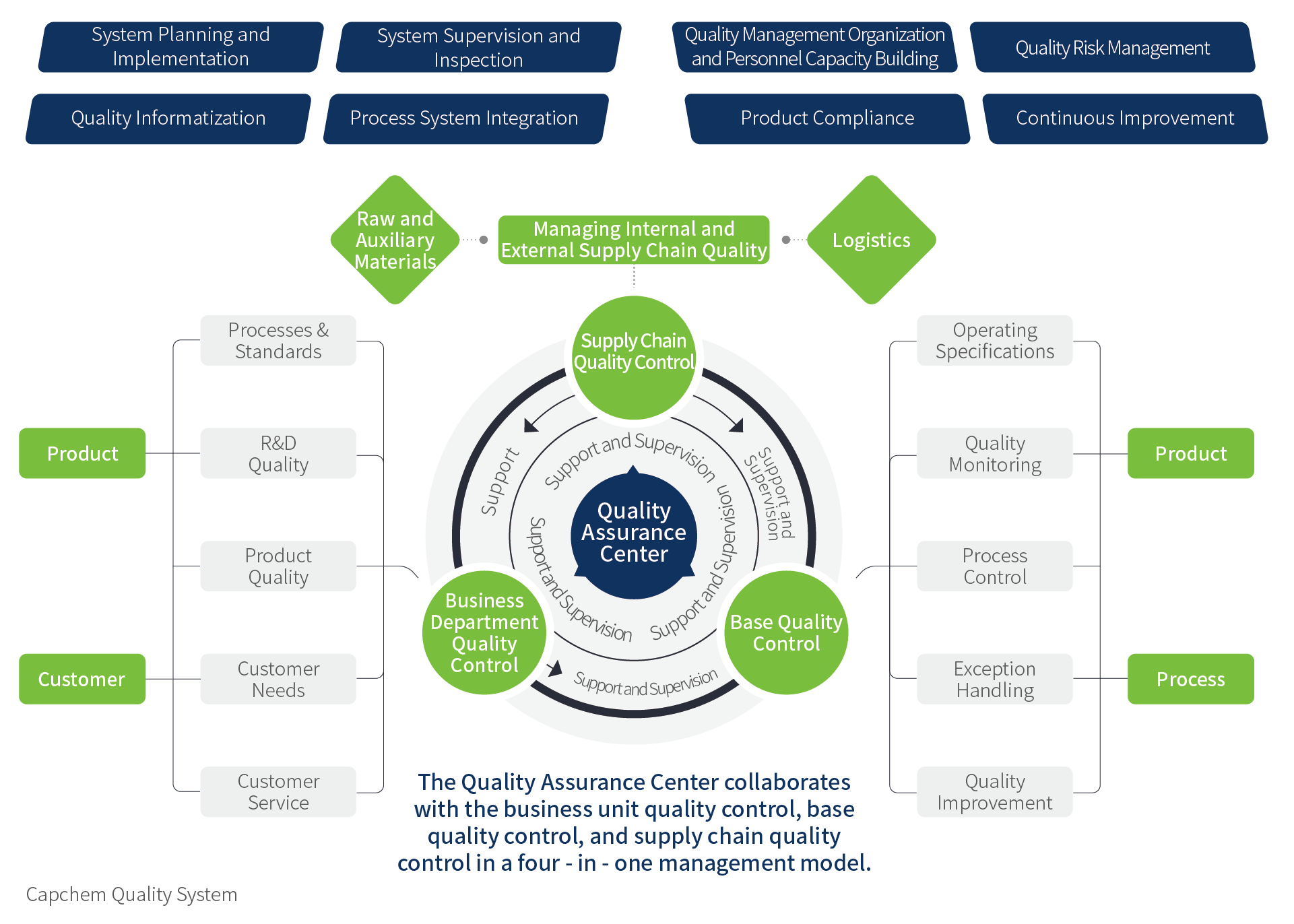

Capchem focuses on perfecting our quality management system to achieve efficient operations and management. The Company has established a quality management structure supported by the Quality Assurance Center, Business Department Quality Control, Quality Control in Supply Chain, and Base Quality Control.

Capchem has established a systematic regulation including Non-Conforming Product Control Procedure, Internal Audit Procedure, Customer Complaint Management Procedure, Regulation on Quality Incident Escalation and Accountability Management, etc. In 2024, the Company responded positively to the internal and external changes by adding a new Business Continuity Management Handbook and revising the BCM Business Continuity Management Procedures. In addition, the Company continues to enhance ESG management capability in the integrated management base, introduces RBA management system, strengthens social responsibility management capability, and strengthens the international competitiveness of Capchem.

Capchem continuously refines our quality system assessment mechanism to achieve dynamic monitoring of quality management effectiveness. The Company has established key quality indicators such as raw material qualification rates, first-pass yield of finished products, and customer complaints, and conduct monthly or annual quality assessments. We also require responsible departments to focus on analyzing the causes of substandard items, formulate corresponding corrective action plans, and continuously elevate the overall level of quality management.

Capchem actively promotes the digital transformation of product quality management and realizes accurate control of quality data in the whole chain from suppliers to clients by building a comprehensive information platform. The Company has deployed a variety of information systems including CRM, SRM, LIMS, MES, OA and SAP to build a complete digital quality management system. The quality of products is guaranteed from the quality control of raw materials, dynamic monitoring of production process, product inspection and sales data analysis.

The Company follows the standards of ISO 9001 and IATF 16949, and regularly implements internal audits of our quality management system to assess our compliance, adequacy and effectiveness, with the aim of grasping the current status of the system and promoting continuous optimization. Meanwhile, the Company introduces third-party organizations to carry out audits, and has obtained a number of authoritative certificates in 2024.

Quality Management Enhancement

Capchem implements full-process, full-life-cycle quality management, covering six dimensions: system, R&D, process, supplier, customer quality management and continuous improvement management. Through process optimization and technological innovation, Capchem is committed to providing customers with high-quality products and services, and driving the sound operation and sustainable development of the whole process.

Quality Culture Building

Perfect quality culture construction provides inexhaustible power for the efficient operation of Capchem's quality system. In order to continuously enhance the effectiveness of the Company's quality management, the Company actively integrates internal and external resources, optimizes the quality management training program, and improves the theoretical knowledge and practical operation skills of the staff in product quality management.Capchem carried out a series of quality management training in the current year, covering quality improvement tools, operation specifications, supplier quality management, system standards, etc., covering 9,418 person-times, with a total of 30,400 hours of training, and a per capita training time of 3.23 hours.

Highlights in 2024

- First pass yield of finished products reached 99.5%

- Raising raw material qualification rates to 96.8%

- No major quality accidents occurred

- Capchem and several subsidiaries obtained ISO 9001, IATF 16949, QC 080000 and CNAS National Laboratory Management System Certification

- Capchem Poland passed IATF 16949 certification & ISO 9001 surveillance audit in 2024